Effluent Treatment Plant By Charm LTD.

We Charm Ltd. is a leading provider of effluent treatment solutions in Bangladesh. Our mission is to ensure the protection of the environment and public health by providing reliable and efficient effluent treatment services.

With 10 years of experience and a team of highly skilled professionals, we have established ourselves as a trusted name in the industry. We use advanced technology and processes FROM MITSHUBISHI and SUMITOMO company to deliver effective and sustainable solutions that meet the needs of our clients.

Our Proposed ETP Plant Manufactures in Bangladesh:

MBR: The term ‘membrane bioreactor’ (MBR) is generally used to define wastewater treatment processes where a perm-selective membrane eg; microfiltration or ultrafiltration is integrated with a biological process – a suspended growth bioreactor. Charm Ltd is a renewed Company that working with Membrane Bio-Reactor (MBR).

MBRs differ from ‘polishing’ processes where the membrane is employed as a discrete tertiary treatment step with no return of the active biomass to the biological process.We supply Mitsubishi MBR & Sumitomo MBR

MBBR: Moving Bed Biofilm Reactor (MBBR) Technology is the cutting edge of biological treatment in Wastewater Treatment Plant (WWTP). The MBBR technology is currently the most advanced solution for COD/BOD Degradation, Nitrification and Denitrification Processes. We work on Biological conventional type ETP enhanced with MBBR.

Conventional Type: Traditional ETP

What Is Effluent Treatment Plant?

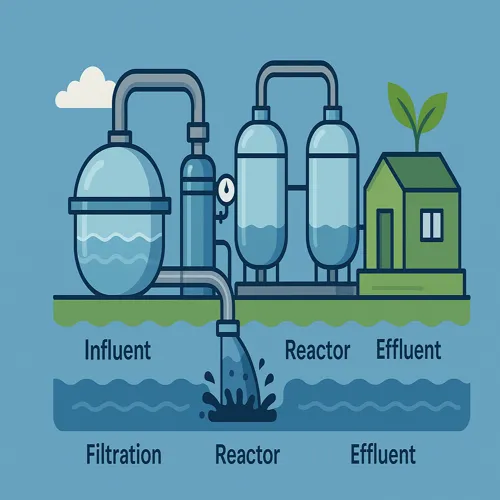

An Effluent Treatment Plant (ETP) is a facility designed to treat and purify wastewater or effluent generated by industrial processes or sewage systems. Its primary purpose is to remove pollutants, contaminants, and harmful substances from the wastewater before it is discharged into the environment or reused. ETPs typically employ various physical, chemical, and biological processes to clean the water, ensuring compliance with environmental regulations and reducing the negative impact on ecosystems and human health.

Why ETP Is Needed?

Where ETP Is Needed?

Hollow fiber membrane STERAPORE

STERAPORE is offering a wide range of filtration application for separation, purification and concentration, such as wastewater treatment and water purification. There are more than 5,000 installed projects all over the world.

Water Treatment System / Material

Our packaged system of DiaFellow series is all-in-one packaged equipment, complete with all the necessary devices for operation including membrane filtration tank, suction pumps, aeration blowers, control panel, etc. Also, we provide water treatment materials, such as bacteria immobilized carriers.

Filter

We offer a wide selection of capsule and cartridge filters equipped with our proprietary polyethylene hollow fiber membrane.

Whether it’s wastewater treatment that combines biological treatment with membrane filtering (MBR), or pure water treatment for drinking water, Sumitomo’s membrane treatment experts can propose high-performance systems that maximize the functions of the POREFLON membrane for water and wastewater treatment. Sumitomo provide world-class membrane treatment facilities at reasonable prices, with complete service programs.

Our Success Stories

We have 5 ETP projects, which all fulfil our clients guidelines and achieve satisfaction, These are :

- Knit Concern Group (Capacity: 6000m3/day)

- Knit Concern Group (Capacity: 2500m3/day)

- Next accessories Ltd (Capacity: 250m3/day)

- Maxcom International (BD) Ltd. (Capacity: 1920m3/day)

- Labib Dyeing Ltd (Capacity: 3600m3/day)

All our ETP’s are biochemical or substances in their properties and can treat water successfully. As influent from industry goes through modern cycles, ETP and waste are treated from influent, and the quality of water becomes improved.

Components of an ETP System

- Actual treatment like screening

- Blower operation

- ECR operation

- Chemicals

- Natural treatment

- Sludge management system

Our ETP Treatment Process

The ETP (Effluent Treatment Plant) treatment process is a multi-stage system designed to treat industrial wastewater before it is discharged into the environment. The process typically begins with preliminary treatment, where large solids and debris are removed through screening and grit chambers. This is followed by primary treatment, where sedimentation tanks allow suspended solids to settle out. Secondary treatment involves biological processes, such as activated sludge or biofilm reactors, to degrade dissolved and organic pollutants. In some cases, tertiary treatment is used for further purification, removing nutrients, heavy metals, and pathogens through advanced filtration, chemical dosing, or disinfection. The treated effluent is then safely discharged or reused, ensuring compliance with environmental regulations and protecting water resources.

Sludge Management System

Sludge Generation: Sludge is the solid waste produced during wastewater treatment.

Thickening: Sludge is thickened to reduce its volume for easier handling.

Dewatering: Further reduces sludge moisture content, making it easier to transport and dispose of.

Disposal Options: Sludge can be disposed of through land application, incineration, landfilling, or composting.

Monitoring and Maintenance: Regular checks and maintenance ensure efficient sludge management.

Why Choose Us as Your ETP Plant Supplier in Bangladesh

- Expertise: We bring extensive experience and expertise in designing and delivering ETP solutions.

- Compliance: Our systems meet Bangladeshi environmental regulations and international standards.

- Customization: We tailor solutions to your unique effluent treatment needs.

- Cutting-Edge Technology: Our ETP systems incorporate advanced, eco-friendly technologies.

- Quality and Reliability: We ensure top-quality materials and equipment for long-term reliability.

- Installation and Maintenance: We offer comprehensive services, from installation to ongoing maintenance.

- Cost-Effective: Our solutions deliver value by reducing operational costs.

- Environmental Impact: We help minimize pollution and promote sustainability.

- Local Presence: We provide local support and expertise in Bangladesh.

- Transparent Pricing: We offer clear, competitive pricing with no hidden costs.